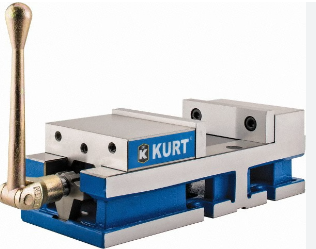

When it comes to precision workholding solutions, the name “Kurt Vise” stands out as a benchmark of quality and reliability. For over 70 years, they have been the industry standard, renowned for their innovative designs and exceptional performance in CNC machining and milling operations.

A Legacy of Innovation

Kurt Workholding, the company behind it, has consistently pushed the boundaries of workholding technology. Their vises are designed to provide precision part clamping for a variety of applications, from basic machining to complex milling tasks. The original Kurt AngLock® vises, for instance, were engineered to minimize jaw deflection and ensure precise clamping.

Versatility and Precision

One of the key features of them is their versatility. The product line includes high precision CNC vises, 5-axis vises, rotary table workholding solutions, and ToolBlox tombstones. These vises are available in various models, including manual, pneumatic, and hydraulic versions, catering to different machining needs.

Key Features of Kurt vise

They are renowned for their precision and reliability in machining operations. Here are some of their key features:

-

AngLock® Design:

This patented design minimizes jaw lift, ensuring the workpiece remains securely clamped during machining, which enhances precision and stability.

-

High Clamping Force:

They provide strong clamping force, which is crucial for holding workpieces firmly in place, reducing the risk of movement during machining.

-

Versatility:

They offer a wide range of vises, including single station, 5-axis, and TriLock vises, catering to various machining needs and applications.

-

Durability:

Built to withstand the rigors of industrial use, they are made from high-quality materials, ensuring long-term reliability and performance.

-

Precision Ground Surfaces:

The vises have precision ground surfaces that ensure accurate positioning and repeatability, which is essential for producing consistent, high-quality parts.

-

Quick-Change Jaw Systems:

Some models feature quick-change jaw systems like CARVESMART, allowing for fast and easy jaw changes, increasing efficiency and reducing downtime.

-

Multiple Mounting Options:

They can be mounted horizontally or vertically, providing flexibility in how they are used in different machining setups.

Which Industries are Getting Benefits from Kurt vise?

They are highly versatile and benefit a wide range of industries due to their precision and reliability. Here are some of the key industries that benefit the most:

-

Aerospace:

Precision is crucial in aerospace manufacturing, and they provide the accuracy needed for machining complex components used in aircraft and spacecraft.

-

Automotive:

The automotive industry relies on Kurt vise for the production of engine parts, transmission components, and other critical parts that require high precision and repeatability.

-

Medical Devices:

Manufacturing medical devices and implants demands extreme precision and reliability, which they deliver, ensuring the quality and safety of medical products.

-

Defense:

The defense sector uses them for machining parts for military equipment and vehicles, where precision and durability are paramount.

-

Energy:

In the energy sector, particularly in the production of components for wind turbines, oil and gas equipment, and power generation systems, they ensure precise machining and long-term reliability.

-

Tool and Die:

This industry benefits from Kurt vise for the production of molds, dies, and other tooling components that require high accuracy and consistency.

-

General Manufacturing:

Across various manufacturing sectors, they are used for a wide range of machining tasks, from prototyping to full-scale production, due to their versatility and dependability.

The AngLock® Advantage

The patented AngLock® design is a hallmark of them. This design ensures that the movable jaw is pulled down and in towards the stationary jaw, reducing jaw lift and providing a more secure grip on the workpiece. This results in higher precision and repeatability, which are crucial for high-quality machining.

High Clamping Force

They are known for their impressive clamping force. For example, the Kurt HD690 vise, a 6-inch pull-type machining vise, offers up to 12,000 lbs. of clamping force. This high clamping force, combined with the vise’s stability and accuracy, makes it ideal for demanding CNC machining operations.

Applications of Kurt vise

They are widely used in various machining and manufacturing applications due to their precision, reliability, and versatility. Here are some common applications:

-

CNC Machining:

Kurt vise is essential in CNC machining centers for holding workpieces securely during milling, drilling, and other machining operations. Their high clamping force and precision ensure accurate and repeatable results.

-

Milling Operations:

Whether it’s vertical or horizontal milling, Kurt vise provides the stability and precision needed to perform complex milling tasks with high accuracy.

-

5-Axis Machining:

Specialized Kurt vise, such as the 5-axis vises, are designed to hold workpieces in a way that allows access to multiple sides without repositioning, which is crucial for intricate 5-axis machining.

-

Rotary Table Workholding:

Kurt vise is used on rotary tables to hold parts securely while the table rotates, enabling precise machining of circular or complex geometries.

-

Tool and Die Making:

In tool and die shops, they are used to hold components during the manufacturing of dies, molds, and other precision tools.

-

Inspection and Quality Control:

They are also used in inspection and quality control processes to hold parts securely while they are being measured or inspected for accuracy.

-

Prototyping:

In prototyping environments, they provide the flexibility and precision needed to create and test new designs quickly and accurately.

Conclusion

In summary, the Kurt Vise is more than just a tool; it is a symbol of precision, reliability, and innovation in the world of machining. Whether you are involved in basic milling or complex CNC operations, they provide the performance and dependability needed to achieve exceptional results.

+ There are no comments

Add yours